- Home

- About us

- Products

- Dealer Enquiry

- Blog

- Contact Us

- Home

- About us

- Products

- Dealer Enquiry

- Contact Us

- 044 -2486 1994

- +91 99623 98222

- sales@nantech.in

- REQUEST A QUOTE

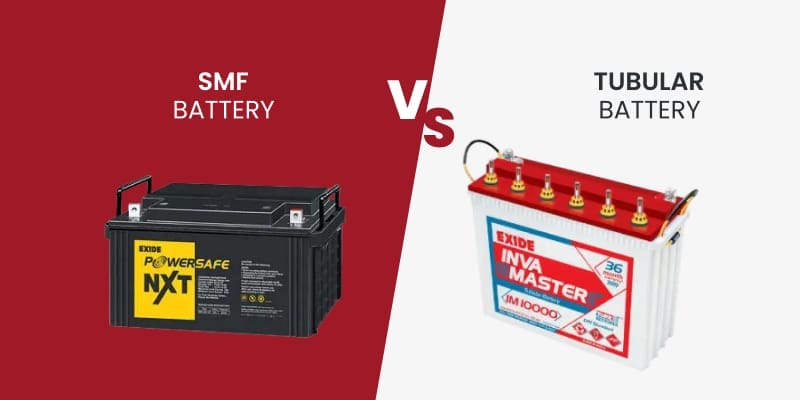

Batteries seem to be everywhere, don't they? They power your car, your phone, and even your wristwatch. But when it comes to understanding the difference between SMF and Tubular batteries, you might find it a bit complex. Looking for the most reliable and efficient option? This article aims to clear up any confusion. Here is a comprehensive analysis comparing these two types of batteries, delving into key aspects, including efficiency, life-cycle assessment, and environmental implications. So, sit back and get ready to make an informed choice.

In your journey to comprehend batteries, you've likely encountered SMF and Tubular batteries. But what do they represent, and how do they function? We need to scrutinise these two categories of batteries, their architecture, and their fundamental operating principles. This scrutiny provides a robust base to grasp the DIFFERENCE BETWEEN SMF AND TUBULAR BATTERY.

An SMF, or Sealed Maintenance-Free battery, falls under the category of lead-acid battery. It's sealed and requires no maintenance or topping up of the electrolyte, making it an ideal choice for places with certain restrictions.

SMF batteries come in various designs to meet diverse needs. Here are the common types:

A standout feature of SMF batteries is their maintenance-free nature. They don't require water or acid top-ups due to their sealed design. This sealing ensures they are leak-proof in the right conditions, eliminating worries about battery acid leakage or water loss during the charge-discharge cycle.

SMF batteries don't emit lead fumes, which adds to their versatility. You can place them near electric equipment or in enclosed rooms without any concerns. Having understood the basics of SMF batteries, it is essential to explore how they stack up against another popular choice - tubular batteries.

Tubular batteries, a larger version of the lead-acid battery, serve frequently in UPS and inverter systems. The name "tubular" springs from the battery's unique design, which flaunts vertically arranged tubes. This clever arrangement not only enhances current flow but also decelerates the corrosion process. Let's look closer at its structure.

The positive plate of a tubular battery resides within a cloth-wrapped tube, which contains the power of the battery's electrodes. This creative design element enhances the battery's performance and extends its lifespan.

Tubular batteries earn acclaim for their durability and ability to provide power for long periods. They also offer more convenience because they need fewer water refills compared to flat plate batteries. Here are some notable benefits of tubular batteries:

In terms of size, tubular batteries come in two versions: short and tall. Short tubular batteries, wider and more compact, are easier to transport. Conversely, tall tubular batteries provide a longer standby period and are ideal for homes with ample storage space.

In the lead-acid battery world, tubular batteries, with their innovative design and robust performance, are clearly in the lead. This is a significant difference between SMF and tubular batteries. In the next section, we'll examine the efficiency of these batteries.

As you investigate batteries, understanding the efficiency of various types becomes essential. Two common types you're likely to come across are SMF and tubular batteries. Each holds unique strengths and weaknesses, especially in terms of energy output, charge retention, and operational conditions. So, we're ready to begin understanding the complexities of these battery types.

The AGM variant of the SMF battery stands out for its efficient power delivery and adaptability to various climate conditions. These batteries charge more rapidly and require less time to recharge than their flooded counterparts, thanks to their effective power delivery.

SMF batteries earn praise for their durability and consistent performance. They are available in different designs, some with a flooded acid cell layout for starter engines or a gel electrolyte for deep-cycle applications. The industry currently prefers options that are specific to particular applications. These come with improved recharge and discharge capabilities, which increase their appeal.

SMF batteries can function in a temperature range from -20 degrees C to 60 degrees C. This gives them a wider adaptability range to different climate conditions compared to flooded lead-acid batteries.

Although SMF batteries might have a higher initial cost, their longer cyclic life and lack of maintenance needs result in cost-effectiveness over time. After discussing the efficiency of SMF batteries, we will focus on another type of battery - Tubular batteries.

Tubular batteries are crucial in renewable energy systems, off-grid energy solutions, critical power configurations, and backup systems. Their reputation for outstanding energy efficiency sets them apart, even outperforming flat plate batteries. The unique design of these batteries, with a larger surface area, enhances this superior efficiency. Let's explore some of the key features and benefits of tubular batteries:

The efficiency and energy storage differences between SMF and tubular batteries make the latter a popular choice in many applications. Now that we've discussed the efficiency of tubular batteries, let's compare their life cycle with SMF batteries.

In your journey to understanding the life-cycle of SMF and Tubular batteries, considering various factors becomes crucial. You'll learn about the lifespan, maintenance needs, and degradation of both types of batteries. Comparing these two commonly used batteries provides insights into their performance and longevity. Let's proceed to examine these aspects.

With the right care, your SMF battery can typically last three to five years, sometimes even longer. However, you must understand that several factors can influence the lifespan of your battery:

The SMF batteries have a long life cycle because of their maintenance-free design. You don't need to stress about adding water or acid to them. This feature marks a significant difference between SMF and Tubular batteries, adding to their extended life cycle.

The oxygen recombination principle in SMF batteries ensures no water loss during the charge-discharge cycle. This clever feature helps in extending their lifespan.

An SMF battery can handle around 200 charge/discharge cycles at a temperature of 25 degrees Celsius with a 100% depth of discharge.

For example, in inverter systems with high current batteries like 150Ah, a cut-off voltage of less than 10.5 volts can shorten the battery life. But, if you set the cut-off voltage at 11.5 volts, it stops the battery from entering a deep discharge state, thus extending its life.

SMF batteries have a longer cyclic life, which makes up for their initial higher cost. Their efficient operation and extended life cycle make SMF batteries a wise investment. Now, let's move on to the life cycle of tubular batteries that could be of interest to you.

Tubular batteries, praised for their outstanding lifespan, owe their durability to a unique design. This design includes vertical spines that enhance current transport and reduce voltage loss in the positive plate, slowing the corrosion process.

The active material of the tubular battery's positive plate resides in a non-woven polyester gauntlet. This deliberate design choice helps to prevent plate shedding, significantly extending the lifespan of these batteries, especially during operations when the battery doesn't reach full charge.

Lead-acid tall tubular batteries typically claim a life cycle of around 1500 cycles. However, usage, charging patterns, and environmental conditions can influence this lifespan.

After serving stationary and renewable applications for 4 - 5 years, lead-acid batteries often face a problem: positive plate grid growth. But, the design of tubular batteries cleverly counteracts this issue. Their sliding design absorbs terminal movement due to positive plate expansion, reducing cracks in the case lid and preventing acid leakage.

Considering the design elements, the difference between SMF and tubular batteries becomes clear. Tubular batteries, with their unique design and ability to withstand various conditions, represent endurance in battery technology. As we discuss further about battery options, it's essential to consider their environmental footprint, a topic we will discuss in the following section.

Grasping the environmental consequences of SMF and Tubular batteries is vital. The creation, disposal, and reprocessing stages of these batteries could inflict substantial impacts on our environment. We must examine how these two kinds of batteries influence the environment.

SMF batteries earn recognition for their efficiency and maintenance-free nature. But have you ever pondered over their ecological footprint? These batteries, thanks to their leak-proof design, shield the environment from possible harm due to water or acid leakage.

Remember, SMF batteries, like other batteries, emit CO2 during their manufacturing process. The growing need for battery materials such as lithium, mined from hard rock mines or underground brine reservoirs, is worth mentioning. They demand more materials for their production compared to traditional combustion engines. A significant chunk of the energy for this extraction and processing comes from fossil fuels, releasing 15 tonnes of CO2 for every tonne of lithium mined. The production process also requires heat within the range of 800 to 1,000 degrees Celsius, most efficiently achieved by burning fossil fuels, contributing to CO2 emissions.

Despite these issues, lithium-ion battery technology, like SMF batteries, turns out to be more climate-friendly when compared to other alternatives. While considering your battery options, consider not only performance and cost-effectiveness but also the broader environmental consequences. Let's delve deeper into this in the context of Tubular batteries.

Tubular batteries, compared to numerous other battery technologies, leave a smaller environmental footprint. Their longer lifespan and lower maintenance needs contribute to less waste and a decreased environmental impact. However, Tubular batteries are not without their downsides.

The creation of these batteries leads to CO2 emissions. As the demand for batteries escalates, so does the production of spent batteries.

Now, let's focus on the environmental consequences of disposing of these batteries. The disposal methods for these spent batteries range widely from landfilling to incineration or even complete or partial recycling. The chosen method depends on the quantity of discarded batteries, existing legislation, and accessible infrastructure.

If not disposed of or processed properly, these batteries can lead to severe environmental problems such as:

When weighing the environmental impact of SMF and Tubular batteries, Tubular batteries, despite their impact, provide a longer lifespan and demand less maintenance.

Your choice between SMF and Tubular batteries should hinge on your specific needs and budget. SMF batteries, which require no maintenance and boast a long lifespan, might catch your interest if you're looking for a battery that demands minimal upkeep. They make an excellent choice for UPS power supply systems.

Contrarily, Tubular batteries need regular maintenance, including adding distilled water and monitoring electrolyte levels.

When it comes to application, SMF batteries prove particularly effective in situations where a backup power supply is crucial. This is often the case in homes or small offices. However, Tubular batteries are better suited for industrial online UPS systems, which demand higher performance and reliability. If you reside in an area with frequent power outages, tubular batteries might serve as your best option.

Performance-wise, SMF batteries excel due to their low internal resistance, which results in efficient power delivery and a faster charging time. On the other hand, Tubular batteries become the preferred choice for applications requiring high current, thanks to their superior energy density.

In conclusion, the cost of SMF and tubular batteries can fluctuate. The most suitable option for you will hinge on your unique needs and budget.

So, we've explored the world of SMF and Tubular batteries together, didn't we? We've understood their composition, efficiencies, life spans, and environmental impacts. Each has distinct advantages and purposes, so your choice should depend on your specific needs. Remember, understanding is the key to power, quite literally in this case! Therefore, don't shy away from seeking advice from battery professionals at Nantech, the reputed inverter and battery dealer in Chennai. As we progress in this technological era, the battery landscape keeps changing. Stay updated and choose the best power solution that suits your needs.

Lead-acid batteries in UPS systems usually come in two types - Sealed Maintenance-Free (SMF) batteries and Tubular batteries. SMF batteries are a favourite because they require low maintenance, they stop leaks, and they have a long lifespan. These features make them an excellent choice for home UPS systems or small office environments. On the other hand, Tubular batteries might need regular attention, but they excel in their efficiency, particularly in places where power cuts happen often. These batteries fit better with industrial online UPS systems. Your specific needs and budget should guide your choice between SMF or Tubular batteries.

Indeed, Sealed Maintenance-Free batteries and tubular batteries demand varying degrees of attention. The former are low-maintenance, eliminating the necessity for distilled water addition. They also boast a resistance to spills and leaks. On the other hand, tubular batteries call for more frequent attention, which includes adding distilled water and keeping an eye on the electrolyte levels.

Indeed, it's possible to replace Sealed Maintenance-Free (SMF) batteries with tubular batteries in a UPS system. But, you have to take into account certain aspects. Tubular batteries carry more weight and have a larger size compared to SMF batteries, which could complicate their installation in certain systems. They also demand regular maintenance, like topping up with distilled water and monitoring the electrolyte levels. However, when it comes to performance, especially in areas that experience frequent power outages, tubular batteries outshine their SMF counterparts. So, whether or not you should switch from an SMF battery to a tubular one boils down to your specific needs and circumstances.

The CCA value of a battery can change depending on the specific model and its manufacturer. So, it's best to check the manufacturer's specifications for the most accurate information. It's important to remember that CCA is a spec often linked with car batteries. They must produce a high current output in cold weather to start an engine.

Sealed Maintenance-Free batteries, also known as valve-regulated lead-acid batteries, don't require maintenance. These sealed lead acid batteries come with a gel or an absorbent glass mat that firmly holds the electrolyte, ensuring no spills or leaks occur.

On the other hand, tubular batteries, frequently referred to as flooded batteries, use a liquid electrolyte. The construction of these batteries includes tubular positive plates and pasted negative plates, which enhances their performance and reliability. But unlike Sealed Maintenance-Free batteries, tubular batteries demand regular maintenance, such as adding distilled water and monitoring electrolyte levels.

A Comprehensive Comparison Guide To SMF Batteries

Exide vs Microtek vs Luminous

Everything You Need To Know About Tubular Batteries

Modular UPS Versus Conventional UPS: Differences Decoded

Uncovering the Game-Changing Benefits of Modular UPS Systems

Maximising Inverter Battery Performance: Key Factors to Consider

Role of UPS Systems in Critical Industries